Incazelo

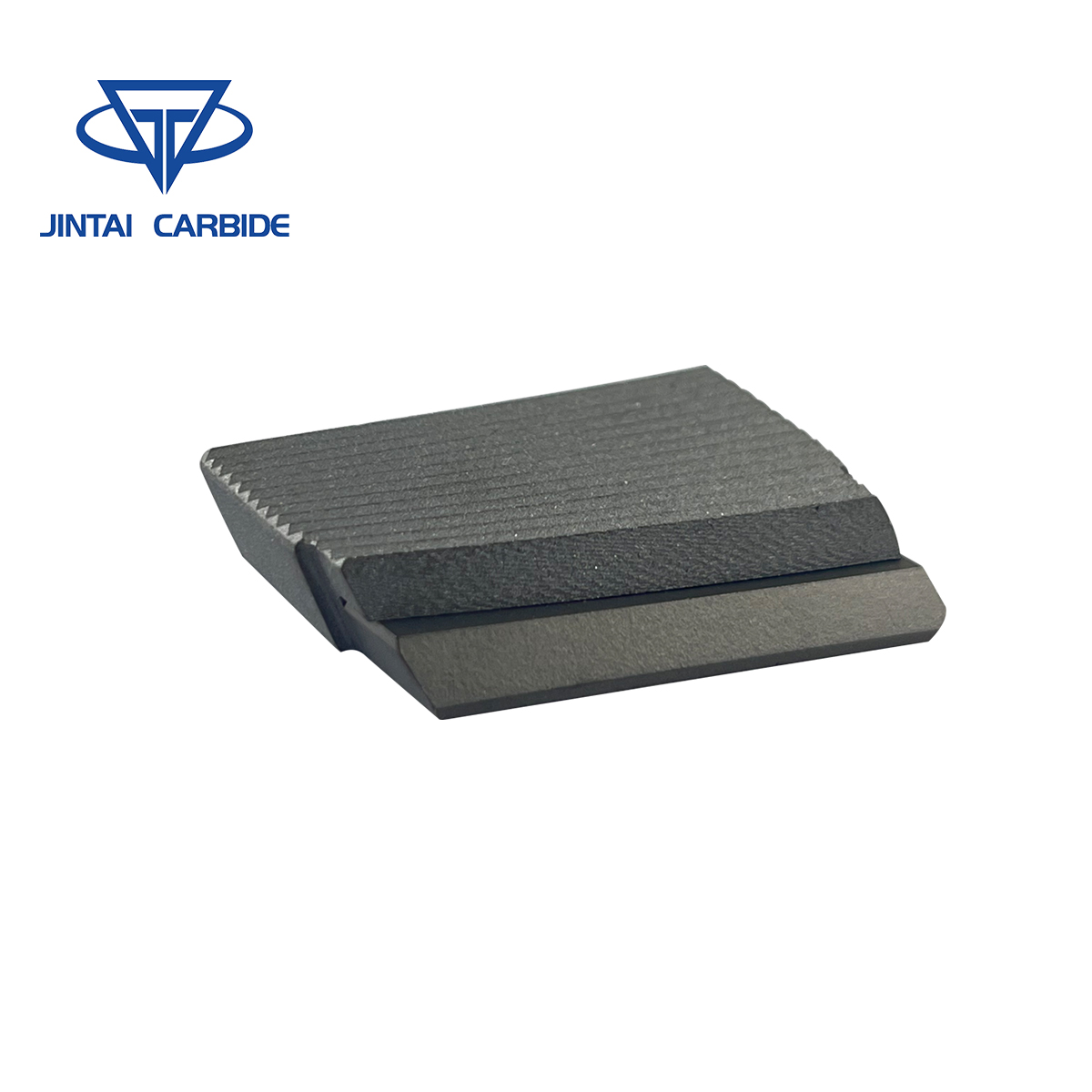

I-Tungsten Carbide Copper Milling Insert, eyaziwa nangokuthi i-scalping cutter yethusi ne-alloy yethusi.

I-blade yethu yokusika ibonisa ukusebenza okukhethekile kokukhipha izinto, okusiza ukugaya okuphumelelayo nokushesha kwezindawo zethusi ukuze kuphakanyiswe ukusebenza kahle kokucubungula.Iklanyelwe izinhlelo zokusebenza ezifuna ukunemba, yenza kahle kakhulu ekuqinisekiseni ukushelela kwangemva kokucubungula nokunemba ezindaweni zethusi.Ngezakhiwo eziphawulekayo ezingagugi, le blade inweba kakhulu isikhathi sayo sokuphila, inciphisa isidingo sokushintshwa njalo futhi ngaleyo ndlela ithuthukise ukusebenza kahle kokukhiqiza kukonke.Idizayinelwe ngokugxila ekunciphiseni ukumelana nokusika, inciphisa ngempumelelo ukumelana ngesikhathi sokusika, ikhawulela ukunqwabelana kokushisa enqubweni yomshini, okunikela ethuluzini elinwetshiwe kanye nesikhathi sokuphila se-workpiece.

Ngaphezu kwalokho, ithuluzi lethu eliyisipesheli lenzelwe ukususwa kwezikali ezixutshwe ne-oxidized kanye nokukhubazeka endaweni ye-copper kanye ne-alloy strips ngemva kokwenza izinqubo zokugaya okushisayo.Leli thuluzi linikezelwe ukugoqa okuqhubekayo kokubili phezulu naphansi kwezinhlangothi zamabhodi ethusi ne-copper alloy agingqelwe esimweni esishisayo.Ilungele izinhlelo zokusebenza kumishini ye-elekthronikhi, njengamatheminali okuxhuma noma izinto zohlaka oluholayo, i-scalping cutter yethu iklanyelwe ukuphatha ngisho nama-alloys ethusi anamandla aphezulu futhi okunzima ukuwasika.Nge-carbide enosimende enamandla aphezulu kanye nobuchwepheshe obuhle kakhulu bokubhuqa, ayigcini nje ngokususa isikhumba esikhumbeni ngokuphumelelayo kodwa futhi ifaka isandla ekuthuthukisweni okuphawulekayo kokukhiqiza kumakhasimende ethu.

Le blade inokusebenza okuvelele kokususa, okuvumela ukugaya okuphumelelayo nokushesha kwezindawo zethusi ukuze kuthuthukiswe ukusebenza kahle kokucubungula.I-blade ihamba phambili ekusikeni okunembayo, iqinisekisa ukushelela nokunemba kwe-copper surface post-processing, iyenze ifanelekele izinhlelo zokusebenza ezinezidingo eziphezulu zekhwalithi yokucubungula.Ngezakhiwo eziphawulekayo ezingagugi, i-blade inweba isikhathi sayo sokuphila, inciphisa imvamisa yokushintshwa futhi ngaleyo ndlela ikhulise ukusebenza kahle kokukhiqiza kukonke.Idizayini ye-blade inezici ekunciphiseni ukumelana, enciphisa ngempumelelo ukumelana ngesikhathi sokusika, ukunciphisa ukunqwabelana kokushisa enqubweni yomshini, nokuba negalelo esikhathini eside sokuphila kwamathuluzi nempilo yomsebenzi.

Uhlu Lwebanga

| Ibanga | Ikhodi ye-ISO | I-Physical Mechanical Properties (≥) | Isicelo | ||

| Ukuminyana g/cm3 | Ukuqina(HRA) | I-TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Ifanele ukwenziwa ngokunemba kwensimbi ekhonjiwe nezinsimbi ezingezona ayoni. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi esakazwayo nezinsimbi ezingenayo ayoni, kanye nokucutshungulwa kwensimbi ye-manganese nensimbi ecishiwe. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Ifanele ukuqedwa kancane kanye nomshini omahhadlahhadla wensimbi eyinsimbi nama-alloys alula, futhi ingasetshenziselwa umshini omahhadlahhadla wensimbi yokusansimbi kanye nensimbi ye-alloy ephansi. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Ifanele ukumba amatshe azungezayo kanye nezingcezu zokumba amatshe. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Ifanele izingcezu zamazinyo amise okweshizolo noma ayisiyingi emishinini yokumba amatshe esindayo ukuze ibhekane nokwakheka kwamadwala aqinile. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Ifanele ukuhlolwa okuqinile kwezinsimbi zensimbi namapayipi ensimbi ngaphansi kwezilinganiso zokucindezela okuphezulu. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Ifanele ukwenza isitembu siyafa. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Ifanele ukwenza isitembu esibandayo nokucindezela okubandayo kuyafa ezimbonini ezifana nezingxenye ezijwayelekile, ama-bearing, amathuluzi, njll. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi engagqwali kanye nensimbi evamile yealloy. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Ifanele ukuqedwa kancane kwensimbi engagqwali kanye nensimbi ye-alloy ephansi. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Ifanele ukwenziwa ngokunemba kwensimbi, ama-alloys asekelwe ku-nickel okushisa okuphezulu, nensimbi enamandla amakhulu. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Ifanele ukusika umsebenzi osindayo wensimbi ne-cast iron. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi nensimbi yokusansimbi. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi nensimbi ecijile, enesilinganiso sokuphakelayo esimaphakathi.I-YS25 iklanyelwe ngokukhethekile ukusebenza kokugaya ensimbi nensimbi. |

| YC45 | I-P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Ifanele amathuluzi okusika umsebenzi osindayo, ohlinzeka ngemiphumela emihle kakhulu ekuguquleni ama-castings nama-forging ensimbi ahlukahlukene. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Ifanele inlaying izingcezu zokumba amatshe ajikelezayo kanye nokubhoboza amatshe aqinile futhi aqinile uma kuqhathaniswa. |

Inqubo yoku-oda

Inqubo Yokukhiqiza

Ukupakisha