Incazelo

1.Ukunquma ama-flash edges, ama-burrs kanye nemigqa yokushisela yezingxenye zokusakha, zokubumba nezokushisela;

2.Qeda ukukhanda izinhlobo ezahlukene zokubunjwa kwensimbi;

3.Ukuqeda amasango e-vane wheel;

4.I-Chamfering, i-rounding kanye ne-chamfer yezinhlobo ezahlukene zezingxenye zemishini;

5.Qedela ukukhanda ubuso bomgodi ongaphakathi wezingxenye zemishini;

6. Ukudweba ngobuciko kwazo zonke izinhlobo zensimbi noma izingxenye ezingezona ezensimbi.

7. I-Tungsten Carbide iwukungagugi okwengeziwe okungafinyelelwa kuzo zombili izingxenye ezihambayo nezimile. Lokhu kuyiqiniso ikakhulukazi ezimweni zesevisi, njengezinga lokushisa eliphezulu, namazinga aphezulu okugqwala nokuhuzuka.

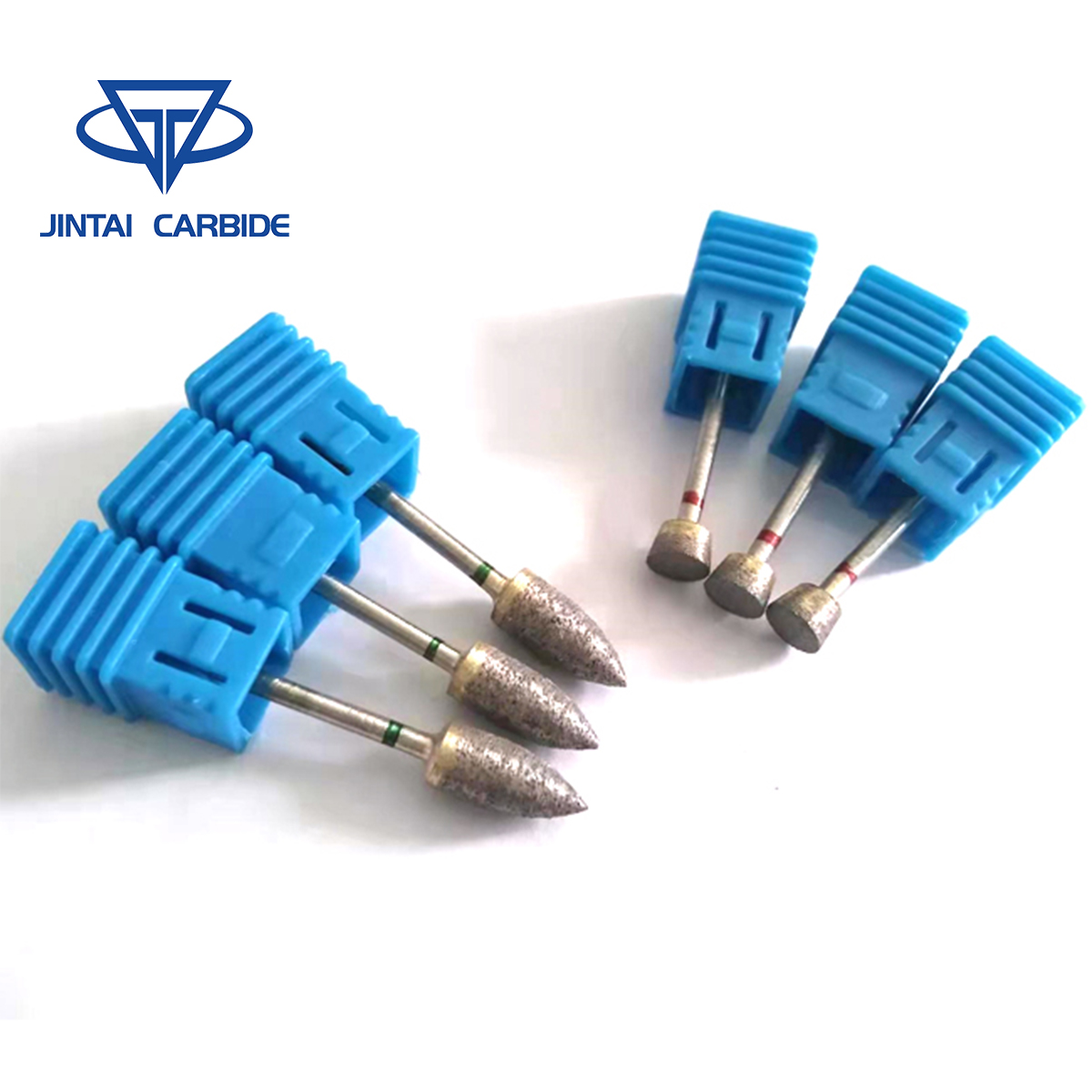

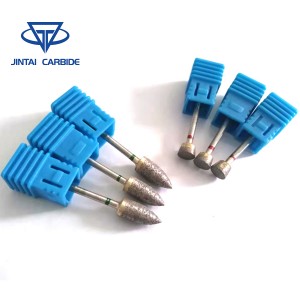

Umbukiso Womkhiqizo

SA

SB

SC

SD

SE

SF

SG

SH

SJ

SK

SL

SM

SN

Uhlu Lwebanga

| Ibanga | Ikhodi ye-ISO | I-Physical Mechanical Properties (≥) | Isicelo | ||

| Ukuminyana g/cm3 | Ukuqina(HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Ifanele ukwenziwa ngokunemba kwensimbi ekhonjiwe nezinsimbi ezingezona ayoni. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi esakazwayo nezinsimbi ezingenayo ayoni, kanye nokucutshungulwa kwensimbi ye-manganese nensimbi ecishiwe. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Ifanele ukuqedwa kancane kanye nomshini omahhadlahhadla wensimbi eyinsimbi nama-alloys alula, futhi ingasetshenziselwa umshini omahhadlahhadla wensimbi yokusansimbi kanye nensimbi ye-alloy ephansi. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Ifanele ukumba amatshe azungezayo kanye nezingcezu zokumba amatshe. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Ifanele izingcezu zamazinyo amise okweshizolo noma ayisiyingi emishinini yokumba amatshe esindayo ukuze ibhekane nokwakheka kwamadwala aqinile. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Ifanele ukuhlolwa okuqinile kwezinsimbi zensimbi namapayipi ensimbi ngaphansi kwezilinganiso zokucindezela okuphezulu. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Ifanele ukwenza isitembu siyafa. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Ifanele ukwenza isitembu esibandayo nokucindezela okubandayo kuyafa ezimbonini ezifana nezingxenye ezijwayelekile, ama-bearing, amathuluzi, njll. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi engagqwali kanye nensimbi evamile yealloy. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Ifanele ukuqedwa kancane kwensimbi engagqwali kanye nensimbi ye-alloy ephansi. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Ifanele ukwenziwa ngokunemba kwensimbi, ama-alloys asekelwe ku-nickel okushisa okuphezulu, nensimbi enamandla amakhulu. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Ifanele ukusika umsebenzi osindayo wensimbi ne-cast iron. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi nensimbi yokusansimbi. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi nensimbi ecijile, enesilinganiso sokuphakelayo esimaphakathi.I-YS25 iklanyelwe ngokukhethekile ukusebenza kokugaya ensimbi nensimbi. |

| YC45 | I-P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Ifanele amathuluzi okusika umsebenzi osindayo, ohlinzeka ngemiphumela emihle kakhulu ekuguquleni ama-castings nama-forging ensimbi ahlukahlukene. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Ifanele inlaying izingcezu zokumba amatshe ajikelezayo kanye nokubhoboza amatshe aqinile futhi aqinile uma kuqhathaniswa. |

Inqubo yoku-oda

Inqubo Yokukhiqiza

Ukupakisha