Incazelo

Ukwehluka kwebanga, ububanzi bosayizi obuphelele, okuvumela ukukhethwa kwamahhala kwamabanga nosayizi bomkhiqizo (YG6/YG6X/YG8/YG8X/YG15/YG20C/YG25...).

Ukuminyana okuhle kakhulu, ubukhulu obufanayo, ukucaba okuhle, ubulukhuni obuphezulu, ukumelana nokugqokwa okukhulu, ukumelana nokugqwala, akukho zimbotshana, awekho amabhamuza, indawo ebushelelezi engenamifantu, imiphetho namakhona ahlukene, i-perpendicularity enhle.Amandla okugoba asukela ku-90 kuye ku-150MPA, izakhiwo zamakhemikhali ezizinzile, ukuhanjiswa kwe-thermal okuphezulu, i-coefficient ephansi yokwandisa okushisayo, namandla okucindezela okuhle kakhulu.

Ibanga lesicelo: Imboni yemishini, i-aerospace, imboni yezimoto, amakhemikhali kaphethiloli, ukwakhiwa kwezokuthutha, imikhiqizo ye-elekthronikhi, ukuhlola uwoyela, ukwenza amawashi, ukukhiqizwa kwezimoto, ukwakhiwa kwemikhumbi, ukukhiqizwa kwezindiza, ukwenza iphepha, ukukhiqizwa kwesikhunta, izingxenye zemishini yemishini, njll.

Amapuleti ethu e-tungsten carbide asetshenziswa ezimbonini ezahlukahlukene nezinhlelo zokusebenza ezidinga izingxenye eziqinile nezihlala isikhathi eside.Kusukela ezimayini nokwakha kuye ekukhiqizeni nasekusebenzeni ngensimbi, lawa mapuleti athuthukisa ukusebenza nempilo yemishini.Kungakhathaliseki ukuthi isetshenziselwa ukusika, ukubhoboza, ukuchoboza, noma esinye isicelo esidinga ukumelana nokugqokwa nokunemba okuphezulu, amapuleti ethu ahlinzeka ngokusebenza okungenakuqhathaniswa nokwethembeka.

Ngokumelana kwawo nokugqokwa okuphezulu, izinto eziqinile kakhulu, ukulawulwa kobukhulu obunembayo okuphezulu kanye nokuqina okungavamile, lawa mapuleti anganweba ukuphila kwezinto zakho zokusebenza, aqinisekise ukuzinza nokusebenza okungenakunqamuka.

Zitholele ubuhle be-Tungsten Carbide Plates ngebhizinisi lakho le-e-commerce eliwela umngcele.Ungabe usabheka njengoba i-premium Tungsten Carbide Plates yethu ihlinzeka ngesixazululo esiphelele sezinhlelo zokusebenza ezihlukene zezimboni, eziqinisekisa ukusebenza okuyingqayizivele nokuqina okuhlala isikhathi eside.

Aklanywe ngobunono ngobunono nobungcweti, Amapuleti ethu e-Tungsten Carbide agqama ngobulukhuni obumangalisayo nokumelana nokuguga, okuwenza abe yinketho yokugcina yokusika, ukugunda, nemisebenzi ehlukahlukene yokumaka.Kusukela ekusebenzeni kwensimbi kuye kwezimbiwa phansi, lawa mapuleti aletha imiphumela encomekayo nokuthembeka, okwenza amaphrojekthi akho abe yimpumelelo.

Ngaphandle kokuqina kwawo okuvelele, ama-Tungsten Carbide Plates ethu abonisa ukumelana nokushisa okukhethekile, okuqinisekisa ukusebenza okungaguquguquki ngisho nangaphansi kwezimo ezidinga kakhulu izinga lokushisa eliphezulu.Zithembele kuzo ukuthi zigcine ubukhali bazo futhi zandise ukukhiqiza ngenkathi unciphisa isikhathi sokuphumula.

Kwa-JINTAI, siziqhenya kakhulu ngokugcina amazinga aphezulu kakhulu.I-Tungsten Carbide Plate ngayinye ihlolwa kanzima, iqinisekisa ukufana nokusebenza kwezinga eliphezulu, ikunikeza amandla okuphumelela emizamweni yakho eyinselele kakhulu.

Phakamisa izinqubo zakho zezimboni ngamapuleti ethu e-Tungsten Carbide aphambili futhi ufakazele ukuthuthuka okuphawulekayo ekusebenzeni kahle kanye nokusebenza kahle kwezindleko.Hlanganyela nathi namuhla futhi uthole umkhawulo wokuncintisana embonini yakho.

Khetha i-JINTAI ukuze uthole Amapuleti e-Tungsten Carbide athembekile, asebenza kahle kakhulu, futhi ukhulule amandla awo angempela ekuqhubekiseleni ibhizinisi lakho ezingeni eliphakeme.Faka i-oda lakho manje ukuze ujabulele ikhwalithi ephezulu nokukhuthazela okufanele amapuleti ethu akunikeze.

Uhlu Lwebanga

| Ibanga | Ikhodi ye-ISO | I-Physical Mechanical Properties (≥) | Isicelo | ||

| Ukuminyana g/cm3 | Ukuqina(HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Ifanele ukwenziwa ngokunemba kwensimbi ekhonjiwe nezinsimbi ezingezona ayoni. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi esakazwayo nezinsimbi ezingenayo ayoni, kanye nokucutshungulwa kwensimbi ye-manganese nensimbi ecishiwe. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Ifanele ukuqedwa kancane kanye nomshini omahhadlahhadla wensimbi eyinsimbi nama-alloys alula, futhi ingasetshenziselwa umshini omahhadlahhadla wensimbi yokusansimbi kanye nensimbi ye-alloy ephansi. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Ifanele ukumba amatshe azungezayo kanye nezingcezu zokumba amatshe. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Ifanele izingcezu zamazinyo amise okweshizolo noma ayisiyingi emishinini yokumba amatshe esindayo ukuze ibhekane nokwakheka kwamadwala aqinile. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Ifanele ukuhlolwa okuqinile kwezinsimbi zensimbi namapayipi ensimbi ngaphansi kwezilinganiso zokucindezela okuphezulu. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Ifanele ukwenza isitembu siyafa. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Ifanele ukwenza isitembu esibandayo nokucindezela okubandayo kuyafa ezimbonini ezifana nezingxenye ezijwayelekile, ama-bearing, amathuluzi, njll. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi engagqwali kanye nensimbi evamile yealloy. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Ifanele ukuqedwa kancane kwensimbi engagqwali kanye nensimbi ye-alloy ephansi. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Ifanele ukwenziwa ngokunemba kwensimbi, ama-alloys asekelwe ku-nickel okushisa okuphezulu, nensimbi enamandla amakhulu. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Ifanele ukusika umsebenzi osindayo wensimbi ne-cast iron. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi nensimbi yokusansimbi. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi nensimbi ecijile, enesilinganiso sokuphakelayo esimaphakathi.I-YS25 iklanyelwe ngokukhethekile ukusebenza kokugaya ensimbi nensimbi. |

| YC45 | I-P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Ifanele amathuluzi okusika umsebenzi osindayo, ohlinzeka ngemiphumela emihle kakhulu ekuguquleni ama-castings nama-forging ensimbi ahlukahlukene. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Ifanele inlaying izingcezu zokumba amatshe ajikelezayo kanye nokubhoboza amatshe aqinile futhi aqinile uma kuqhathaniswa. |

Inqubo yoku-oda

Inqubo Yokukhiqiza

Ukupakisha

-

Amathiphu we-Tungsten Carbide ISO Standard Brazed

-

I-Tungsten Carbide Iyafa - Ukunyathela Kufa Futhi ...

-

I-Tungsten Carbide Surface Milling Insets Ye-Al...

-

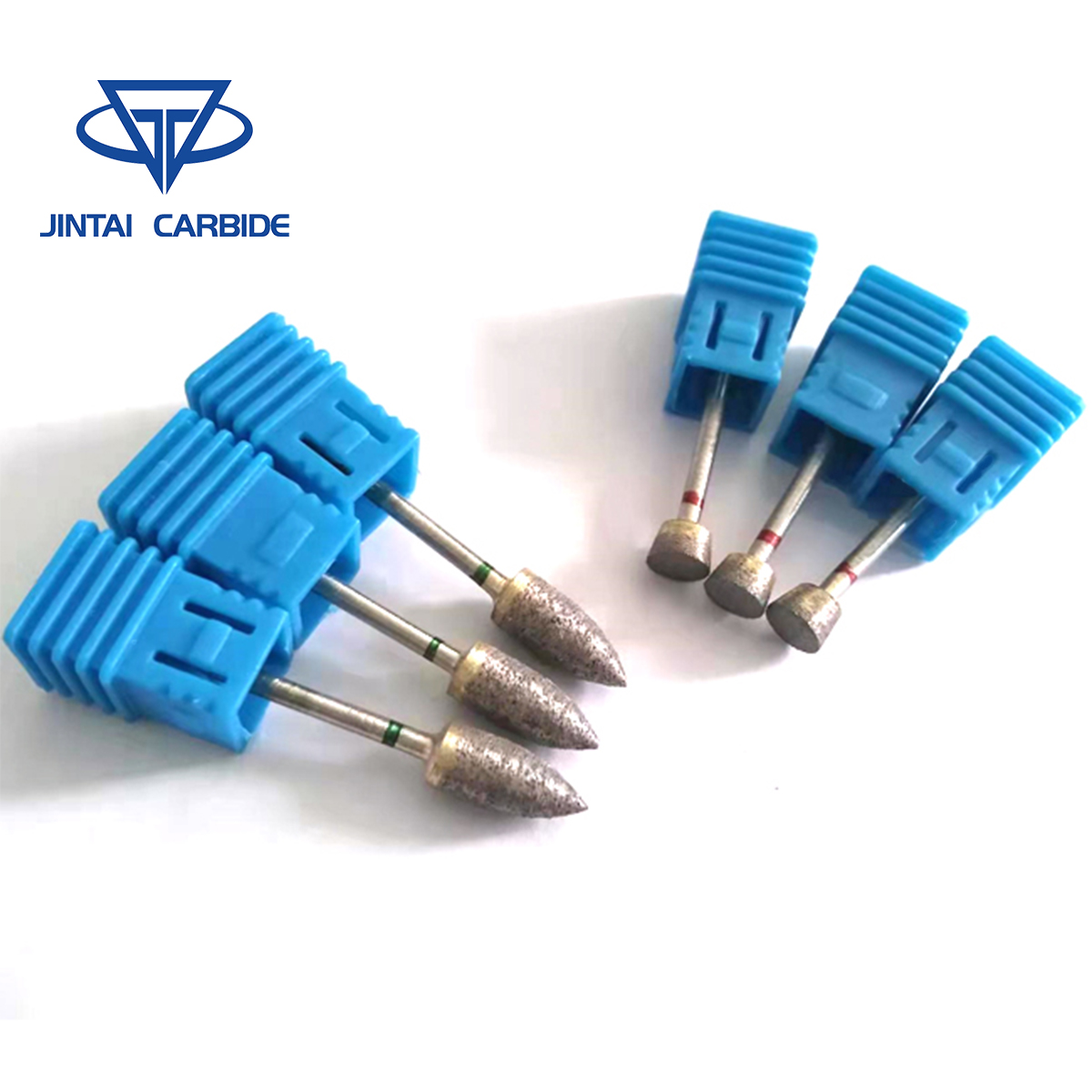

I-Tungsten Carbide Rotary Burr Noma I-Die Grinder Bits

-

I-Tungsten Carbide Strips - I-Square Tungsten ...

-

I-Tungsten Carbide Fiber Optic Cleaver Replacemen...