Uhlu Lwebanga

I-Zhuzhou Jintai Cemented ikhiqiza izinhlobo ezingama-2000 zamathiphu ajwayelekile ahambisana ne-ISO (International Standard), i-BSS (i-British Standard), i-SMS (i-Swedish Standard) kanye ne-DIN (i-German Standard).I-Zhuzhou Jintai Cemented ithuthukise amabanga ayo e-Sintered Metal Cutting ahambisana namazinga e-ISO.

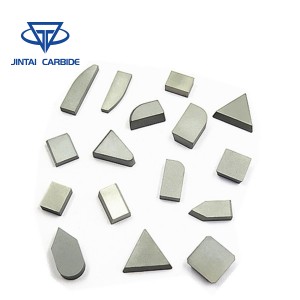

Ngaphandle kwamathiphu ajwayelekile, iZhuzhou Jintai Cemented iyaqhubeka nokuzama ukuthuthukisa amathiphu akhethekile enziwe ngokwezifiso ezimbonini ezehlukene njengezezimoto, ezobunjiniyela, izinsiza zezicathulo, i-Textile, ushukela, njll. Eminye yemikhiqizo evelele ethuthukiswe ngempumelelo i-Blanks for Rotary Burrs, Amathiphu efomu. amathuluzi, amafulethi emimese, amathuluzi e-Scarfer, amathiphu wamathuluzi okugaya, izinduku zamathuluzi ayisicefe, izikhala zokusika izikebhe, njll.

Izici

1. 100% impahla eluhlaza ye-WC+CO

2. Intengo ye-Wholesale kanye nekhwalithi ephezulu ezinzile

3. ISO standard

4. Isevisi ye-OEM ne-ODM.

5. Isicelo: Ukuphenduka, ukugaya, ukuhlanganisa nokuhlukanisa njll. Ukuze uqedele, u-semi-finishing, insimbi ekhanyayo ne-roughing, i-casting steel, i-alloy steel, insimbi yokusansimbi, insimbi engagqwali njalonjalo.

6. Isici esivelele: ikhwalithi enhle yokusika, ukumelana nokugqoka okuphezulu nokusebenzisa isikhathi eside.

7. Uhlobo olwenziwe ngokwezifiso: singakhiqiza i-carbide blade njengomdwebo wekhasimende, usayizi kanye nemfuneko.

Uhlu Lwebanga

| Ibanga | Ikhodi ye-ISO | I-Physical Mechanical Properties (≥) | Isicelo | ||

| Ukuminyana g/cm3 | Ukuqina(HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Ifanele ukwenziwa ngokunemba kwensimbi ekhonjiwe nezinsimbi ezingezona ayoni. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi esakazwayo nezinsimbi ezingenayo ayoni, kanye nokucutshungulwa kwensimbi ye-manganese nensimbi ecishiwe. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Ifanele ukuqedwa kancane kanye nomshini omahhadlahhadla wensimbi eyinsimbi nama-alloys alula, futhi ingasetshenziselwa umshini omahhadlahhadla wensimbi yokusansimbi kanye nensimbi ye-alloy ephansi. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Ifanele ukumba amatshe azungezayo kanye nezingcezu zokumba amatshe. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Ifanele izingcezu zamazinyo amise okweshizolo noma ayisiyingi emishinini yokumba amatshe esindayo ukuze ibhekane nokwakheka kwamadwala aqinile. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Ifanele ukuhlolwa okuqinile kwezinsimbi zensimbi namapayipi ensimbi ngaphansi kwezilinganiso zokucindezela okuphezulu. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Ifanele ukwenza isitembu siyafa. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Ifanele ukwenza isitembu esibandayo nokucindezela okubandayo kuyafa ezimbonini ezifana nezingxenye ezijwayelekile, ama-bearing, amathuluzi, njll. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi engagqwali kanye nensimbi evamile yealloy. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Ifanele ukuqedwa kancane kwensimbi engagqwali kanye nensimbi ye-alloy ephansi. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Ifanele ukwenziwa ngokunemba kwensimbi, ama-alloys asekelwe ku-nickel okushisa okuphezulu, nensimbi enamandla amakhulu. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Ifanele ukusika umsebenzi osindayo wensimbi ne-cast iron. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi nensimbi yokusansimbi. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Ifanele ukwenziwa kwemishini enembile kanye nokuqedwa kancane kwensimbi nensimbi ecijile, enesilinganiso sokuphakelayo esimaphakathi.I-YS25 iklanyelwe ngokukhethekile ukusebenza kokugaya ensimbi nensimbi. |

| YC45 | I-P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Ifanele amathuluzi okusika umsebenzi osindayo, ohlinzeka ngemiphumela emihle kakhulu ekuguquleni ama-castings nama-forging ensimbi ahlukahlukene. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Ifanele inlaying izingcezu zokumba amatshe ajikelezayo kanye nokubhoboza amatshe aqinile futhi aqinile uma kuqhathaniswa. |

Inqubo yoku-oda

Inqubo Yokukhiqiza

Ukupakisha